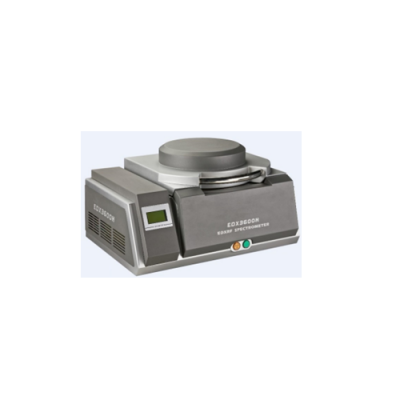

Direct-reading Optical Emission Spectrometer

Direct-reading Optical Emission Spectrometer

Description

Based on the Multi-CCD detector and total spectrum technology, Optical Emission Spectrometer OES 8000S detect all the spectral lines within the range of wavelength; so it is extremely easy to install and add the matrix, channels and analytical program. With a compact size, it is easy to maintain and locate in the laboratory. OES 8000S is a good choice of the complex analysis for ferrous and nonferrous metals in one instrument.

Performance advantages

1.Thanks to the Multi-CCD detector and total spectrum technology, it is easier to install and add the matrix, channels and analytical program in Sky-ray or customers' laboratory.

2.Require smaller space for laboratory because of the compact size.

3.Work for 24/7 to serve your business with high stability and reliability.

4.Fast way to analyze and demonstrate the results within 30 seconds.

5.The operation and maintenance are simple and convenient for operators.

6.All of the typical analytical programs are calibrated in Sky-ray, which are more accurate and test more types of metal grades.

7.Easy to calibrate the instrument with the standardization samples.

8.Without chemical reagents, the analysis process is safe and ecofriendly.

Application fields

The element analysis for metal materials is a traditional work for the research and development, quality control, process control and other related works in the field of the metal smelting, casting and processing industry.

U-THERM Optical Emission Spectrometer is widely used in the element analysis of ferrous and non-ferrous metal. The instrument can simultaneously analyze dozens of elements with a fast, accurate and stable performance, meeting the requirements in industrial development, process control, incoming inspection, product sorting, etc.

U-THERM Optical Emission Spectrometer provides a convenient, eco-friendly and low-cost solution for metal analysis, making the R&D, production process and product quality more controllable, helping users upgrade the level of technology and quality; while accelerating the relevant procedures and creating economic and environmental benefits for users. Optical Emission Spectrometer has been a typical device to evaluate the level of technology and product quality for a factory.

Technical Specifications

Light chamber design

Pasing Longge structure with diameter of Roland circle being 400mm

Wavelength range 134-680nm

Pixel resolution 1 Opm

Constant temperature 32.5士0.5°C

Special materials to ensure that the light

chamber deforms to minimum

Concave Grating

Engraved line density 24001/mm

Primary spectral line dispersion rate:1.04nm/mm

Software

Polynomial correction method to calculate the concentration ratio

Matrix correction

lntensity standardized correction

Material grade type re-calibration

Automatic correction of the interference

between the spectral lines of the elements

Recognition of grade library

One-key position correction

One-key printing function

The test results are output in different

formats

National Standard Sample Library

Excitation light source

High energy plasma spark light source technology

High-energy pre-sparking technology (HEPS)

Frequency 100-1 OOOHz

Excitation Platform

3mm analysis spacing on sample platform

Spray electrode technique

Dimension

Height 435mm, length 900mm, width 600mm

120 kg

Power

Maximum power 1500 W

Standby power 70 W

Detector

High-pe「formance linear array CMOS

Analysis time

30 seconds or less, depending on sample type

Typical results

Low alloy steel GBW1398

Elements | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

Reference Value | 0.499 | 2.140 | 0.798 | 0.029 | 0.021 | 0.974 | 1.970 | 0.830 | 0.303 |

Results | 0.491 | 2.168 | 0.818 | 0.027 | 0.019 | 0.953 | 1.939 | 0.820 | 0.291 |

Elements | V | Ti | AI | Nb | W | B | Co | Zr | |

Reference Value | 0.469 | 0.082 | 0.027 | 0.124 | 1.530 | 0.0047 | 0.238 | 0.051 | |

Results | 0.475 | 0.083 | 0.025 | 0.127 | 1.501 | 0.004 | 0.230 | 0.055 |

Stainless steel YSB S 11378a-2008

Elements | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

Reference Value | 0.066 | 0.760 | 1.160 | 0.030 | 0.0091 | 17.490 | 8.230 | 0.205 | 0.355 |

Results | 0.066 | 0.790 | 1.180 | 0.027 | 0.007 | 17.573 | 8.173 | 0.189 | 0.344 |

Elements | V | Ti | AI | Nb | W | Co | |||

Reference Value | 0.061 | 0.006 | 0.014 | 0.011 | 0.021 | 0.099 | |||

Results | 0.059 | 0.007 | 0.018 | 0.010 | 0.029 | 0.094 |

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG