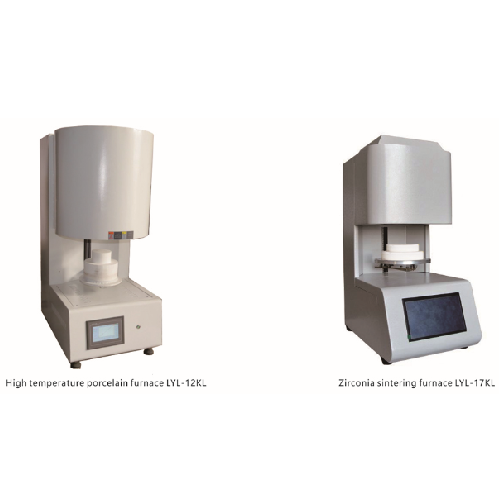

High temperature dental furnace

Product ID: LYL-12KL, LYL-17KL, LYL-14XL, LYL-16KZL

This equipment is mainly used in the processing of dental ceramic powder. Dental furnace are widely used for the sintering and crystallization of the Zirconium dioxide crown; Can also be widely used in universities, research institutes, industrial and mining enterprises to do powder, military, aerospace, electronics, metallurgy, medicine, ceramics, glass, machinery, new materials development, special materials, refractory materials, building materials, chemicals, metal sintering, experiment for the metal heat treatment and production ideal equipment.

Technical characteristics

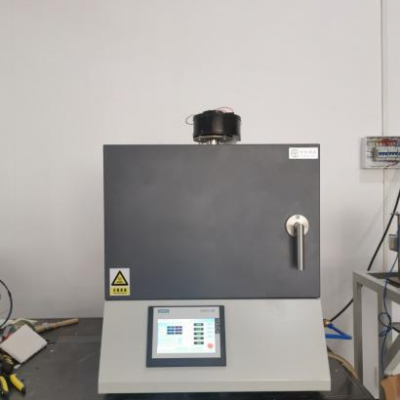

1. This equipment introduces foreign advanced technology, self-developed and produced high-efficiency, energy-saving and environmental protection new electric furnace. The equipment has unique design technology, beautiful appearance, advanced and reasonable structure, simple and convenient operation, high-quality cold-rolled steel plate and precision CNC machine tool. Processing, luxury, beautiful two-color imported epoxy powder electrostatic spray process, processed, high temperature, corrosion resistance, long-term non-fading;

2. The furnace has a unique circular furnace design, the heat element makes up the uniform heatment around the furnace, the temperature field is uniform, the surface temperature of the double-layer heat-resistant furnace is close to room temperature, and it’s with the advantages of rising, maintaining and cooling which can be adjusted arbitrarily. The furnaces are all made of imported ultra-high temperature composite fiber materials through a unique numerical control process. They are resistant to thermal shock, strong heat resistance, good corrosion resistance, no collapse, no crystallization, no slag, no pollution, long service life;

3. The control system adopts microcomputer intelligent adjustment technology, with PID adjustment, automatic control, self-settling function, 50-segment program, and can prepare various heating-up, constant temperature and cooling programs, high temperature control precision, high energy saving and high stability

4. The protection device adopts independent protection: over temperature, over pressure, over current, broken couple, power off, leakage, short circuit and other protections. The degree of automation is high, and the indicators have reached the international advanced level;

5. The lifting type loading platform has a scientific and reasonable structure and has become the mainstream sintering furnace type in the field of zirconia or alumina crystallization.

Additional configuration

1. In addition, through the control software independently developed by our company, the electric furnace is connected with the computer, which can realize remote control of single or multiple electric furnaces, start electric furnace, stoop electric power, set temperature control program, store temperature control program, view historical curve, printing history curves, etc.;

2. True color touch screen, PLC control, easy to operate, real-time temperature control detection, heating dynamic curve display, furnace temperature can be corrected regularly.

Furnace size

Crucible volume (L) | Voltage (V) | Power (kw) | Temperature control accuracy |

Φ100*100 | 220 | 2 | ± 1 ℃ |

Φ120*120 | 220 | 2.5 | ± 1 ℃ |

Temperature: 1200 ℃, 1700 ℃ | |||

1. Chamber size and temperature according to customer need;

2. Control system: computer control, touch screen control, micro-computer control can be optional.

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG