Intelligent Laser Particle Size Analyzer

Intelligent Laser Particle Size Analyzer

Model ID: PSA2005

Overview:

Intelligent full automatic laser diffraction particle size analyzer with principle of Mie Scattering to precisely determine the particle size distribution from 0.1μm to 1000μm. It enables you understand materials well, such as abrasives, adhesives, agrochemical, barite, Batteries, Bentonite, Boron Carbide, Brucite, Bubble, Calcite, Calcium Carbonate, Carbon Black, Catalysts, Cement, Ceramics, Chemicals, Clay, Coal, Coatings, Corundum, Cosmetics, Diamond Powder, Dolomite, Diatomite, Emulsion, Environmental, Explosives, Ferrite, Flour, Fluorescent, Fluorite, Food & Beverage, Food Additive, Graphite, Grinding, Inks, Kaolin, Medicine, Metal Powder, Mica, Milling, Minerals, Oxides, Paints, Paper, Petrochemical, Pharmaceuticals, Pigments, Plaster, Plastics, Polymers, Quartz, Refractory, Resins, Silica, slurry, Soil Sediments, Starch, Sulfur, Synthetics, Talc, Toners, Tourmaline, Wollastonite, Zeolite, Zirconium Silicate etc. Industry.

Main Specifications:

Model Name | PSA2005A | PSA2005B | ||

Standard | ISO13320-1:1999,GB/T19077.1-2008,Q/0100JWN001-2013 | |||

Principle | MIE Scattering Principle | |||

Size range | 0.01μm-780μm | 0.1μm-1000μm | ||

Photodetectors | 90 pcs | 69 pcs | ||

Accuracy error | <1% (Deviation of D50 on national standard sample) | |||

Repeatability error | <1% (Deviation of D50 on national standard sample) | |||

Laser | High performance He-Ne Laser λ= 632.8nm, p>2mW Service time>25000 hour | |||

Wet dispersion | Ultrasonic | Frequency:40KHz Power:35W, Time: ≥1S | ||

Agitator | Revolutions Speed: 0-3000RPM (Adjustable) | |||

Circulation | Rated Flow:8L/min Rated Power:10W | |||

Sample tank | Volume: 350mL | |||

Operation mode | Manual and Full automatic | |||

Optical alignment system | Full automatic optical path alignment system | |||

Software function | Analysis mode | Free Distribution, R-R Distribution, Logarithm Normal Distribution, Mesh number classification etc. | ||

Statistic Method | Volume Distribution, Quantity Distribution | |||

Statistic Comparison | Several Testing Results of samples Different batches of samples testing result, Samples before and after processing, Test result of samples in different time. | |||

User-defined Analysis | Figure out percentage according to the particle size Figure out particle size according to the percentage Figure out percentage according to the particle size range Meet demands of representation of particle test in different industries | |||

Test Report | Word, Excel, Photo( Bmp), Text etc | |||

Multiple-language Support | Multiple language Support | |||

Intelligent operation | Automatically control water inflow, dispersion, test and analysis. Better Repeatability after remove human-factor | |||

Testing speed | <2min/time (including all the procedures) fastest measuring time<10S | |||

Running temperature | 15 ℃ -35 ℃ | |||

Outer dimension | L85cm*W39cm*H45cm | |||

Net weight | 40Kg | |||

Main Features:

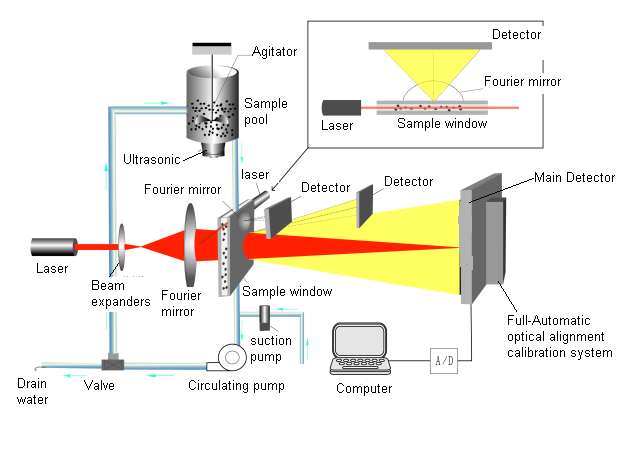

1, Advanced design of light path:

A patented technique of Fourier transform of converging light released the scattered light at large-scattering-angles from the restriction of the aperture of the Fourier lens. The focal length is reduced to enhance the resolution of the instrument, and ring shaped of multi-element silicon photo-diode ensure gathering all the light signals of particles, highly improve the resolution.

2, Built-in intelligent liquid dispersion units:

We carefully aligned the stirring set-up, the ultrasonic dispersing unit and the sample circulation pipes, and fixed them inside the instrument. Such a built-in design effectively prevents the inhomogeneous dispersion and sedimentation of big particles, which can be observed in the designs that these dispersing units are separated from the instruments, where the sample circulation pipes are therefore too long, the sample will be sufficiently dispersed.

3, Unconstrained free fitting analysis patent techniques:

The particle analysis software uses a unique unconstrained data fitting analysis patent technique that we developed to obtain data of real particle size distribution, this is particularly important for researchers.

4, Modern measurement control:(Intelligent SOP Operation)

Users can perform all measurement procedures by simply operating on the PC and have ideal results in a very short time.

6, User-friendly Operation:

manual mode and the automatic mode, freely choose, to measure according to the sample features. In some conditions (e.g. the sample have unknown features or there are special requirements for the measurements), users can make a test measurement in the manual mode first, and after having an idea of the sample features and the measurement conditions, measure the samples in the automatic mode.

7, Three-dimension automatic light path alignment system:

A precise four phase hybrid stepping motor automatically aligns the optical path and can adjust it at any moment, precision is up to 0.1um, this releases users from manual adjusting the optical path and improved accuracy and stability of the measurement results.

8, Quick measurements:

set “automatic” mode, all operation procedures are performed automatically, automatic water supply, automatic ultrasonic sample, stirring, circulation, background testing, sample testing, analysis, draining and cleaning, which significantly reduces the time for measurements, the full process < 2 minutes.

9, Data analysis:

Errors in the data are rejected and the measurement results are automatically processed. Manual data processing is not necessary and the output is more standard.

Ⅱ test analysis view

After testing, if necessary, to select records generated an average result, the system analyzes the formation of the recording. When the automatic mode test, without data processing, forming and maintaining a comprehensive system automatically analyzed test records.

![1667274700157491.png 6(756)%WZWC1}H1@HY4]0OQ.png](/Uploads/image/20221101/1667274700157491.png)

Scheme:

Adopt Patents Technology:

l Optical bench design is protected by patent No.- ZL 2014 2 0378380.8,

l Three dimensional-optical bench alignment system is protected by patent No.- ZL 2013 2 0835882.4.

l MIE scattering principle application patent No.- ZL 2013 2 0812021.4.

l Dual laser beam orthogonal application is protected by patent No.-ZL 2007 2 0025702.0

l Wet circulation installation is protected by patent No.-ZL2010 2 0593526.2

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG