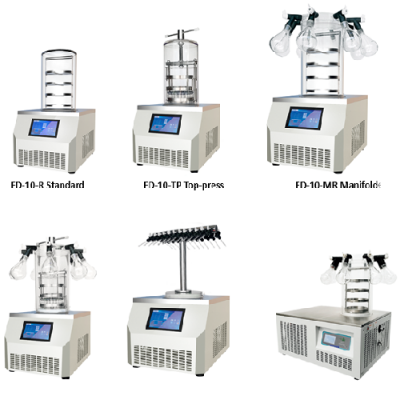

Vacuum freeze dryer

Product ID:LGJ-50E

Features

1. Structural design conforming to biopharmaceutical standards. The internal roundness, surface roughness, shelf smoothness and internal materials of the freeze-drying chamber all meet the pharmaceutical standards.

2. The control system is stable and reliable. With PLC programmable logic control system and 7-inch color touch screen, the system runs more stably and reliably, human-computer interaction friendly, can realize remote control of mobile terminal and computer terminal, with three levels of authority.

3. Real-time display and record vacuum, cold trap temperature, material temperature, shelf temperature and form freeze-drying curve. Store data once a minute. Continuously record material and equipment status data. Support data offline browsing, analysis, printing and storage. Configure USB communication interface and TCP interface.

4. The freeze-drying process can be controlled. The freeze-drying process is automatically controlled by programmable program. Semi-automatic or full-automatic control can be switched in real time to realize the whole process parameter control of freeze-drying process.

5. Separation design of freeze-drying chamber and cold trap chamber has realized the standard of

drug-grade pilot plant and improved the efficiency and ability of water catching.

6. Using medium circulation technology. The shelf temperature is controlled, the temperature of the plate is uniform and controllable, flat plate, good heat and cold conduction.

7. Double cascade refrigeration technology. The original imported fully enclosed compressor unit and the international standard green environmental protection cold coal are adopted to achieve rapid refrigeration, low cold trap temperature and strong water capture capacity.

8. With the compressor secondary start delay protection and pressure overload protection system.

9. The drying chamber adopts high-pressure, low-temperature-resistant aerospace acrylic material with high transparent door to observe the whole process of material freeze-drying change.

10. The rest plate silicone oil refrigeration and heating, with temperature, speed adjustable, controllable, to achieve in-situ pre-freezing and sublimation function.

11. Configure the interface of the negative pressure aeration system. Built-in 0.2μm filter element to reduce secondary pollution of the sample, backfilling with nitrogen or inert gas

12. Cold trap has automatic frost function.

13. Optional automatic capping system.

14. Optional clean room installation, and provide clean room installation solutions.

15. Optional vacuum adjustment function to realize freeze-drying process exploration.

16. Optional eutectic point online test function to better optimize the sample sublimation process;

17. Optional wireless remote real-time monitoring and chart recording of the computer.

18. Optional intermediate isolation valve: pressure rise test and vacuum degree adjustment.

Technical indicators

※ Standard cold trap temperature (no-load): ≤-80℃ (ambient temperature ≤30℃)

※ Ultimate Cold Trap Temperature (no-load): ≤-83℃ (ambient temperature ≤25℃)

※ Maximum water catch:15 Kg

※ Standard vacuum (no load): ≤10 Pa

※ Ultimate vacuum: 1 Pa

※Material tray, freeze-dried quantity: Bulk material can be loaded 5L

4+1 shelf, layer spacing 68 mm, freeze-dried area 0.5m2; 1870 pcs of Φ16mm Vials or 980 pcs of Φ22mm Vials can be loaded

※Shelf size (length × width): 300mm×420mm

※Shelf temperature control range: -50℃~70℃, temperature control accuracy: ±1℃

※Material Temperature Probe: One piece per Layer

※Host dimensions (length × width × height): 1400mm×730mm×1380mm (without top-press)

※Machine power: 4200W

※Applicable power supply: AC380V 50Hz

※Machine weight: 650Kg

※Applicable environment: ambient temperature ≤ 30 ° C

※The main configuration: one host, one vacuum pump.

Optional accessories:

Vacuum degree adjustment, imported vacuum pump, high speed vacuum pump oil, vacuum pump inlet dust filter, vacuum pump exhaust port oil mist filter

Inert gas inflation interface, eutectic point tester

GMP clean room installation

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG