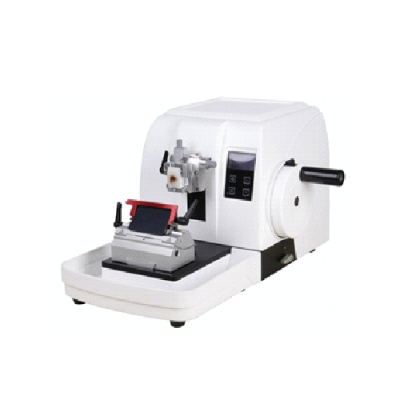

Fully Automated Microtome

Product ID:SF-3398

Features:

§ This machine uses a streamlined design, with advanced features, stable and reliable performance and ease of use;

§ The feeding system uses an intelligent control mechanism; enabling quick switching between manual or automated smart sectioning modes; automatic slicing speed is adjustable;

§ Advanced drive systems and multiple functions including sectioning, trimming, fast forward, fast backward, quick mode conversion including automatic retraction;

§ Incorporates an international advanced screw motion mechanism to ensure precision, thus achieving superior sectioning performance;

§ Pure-green digital display of slice thickness, trimming thickness, slice count and slice speed;

§ Trimming and slicing are operated under a control system, and can be switched easily. The automated slicing controller can be equipped at either the left or right side; when automated slicing controller is off, semi-auto slicing or trimming can still be performed;

§ Automatic sectioning speed is continuously adjustable

§ With safety and emergency braking systems, security alarm systems, driver overload protection and an auto-sleep protection system;

§ Features easy and fast switching between different specimen clamps (two options: paraffin block clamp and cassette clamp);

§ Hand-wheel balance is precisely adjusted and can be locked at any position to ensure safety of operation;

§ Blade holder can be laterally moved to avoid moving the blade with direct contact, thereby enabling use of the entire length of the blade. (three different segments);

§ The red protection bar on the blade holder covers the whole length of blade to protect the user and the push bar enables easy changing of the blade;

§ Hand-wheel balance is precisely adjusted and can be locked at any position to ensure the safety and convenience of sectioning;

§ Large-volume waste tray is easy to remove, and items such as deposable blades can be stored on the top of the housing.

Technical Specifications

§ Section Thickness Setting Range: 0.25—100μm

0.25—2.5μm increment 0.25μm

2.5—5μm increment 0.5μm

5.0—10μm increment 1μm

10—30μm increment 2μm

30—60μm increment 5μm

60—100μm increment 10μm

§ Trimming Thickness Setting Range: 1—600μm

1—10μm increment 1μm

010—020μm increment 2μm

020—050μm increment 5μm

050—150μm increment 10μm

150—600μm increment 50μm

§ Retraction Setting Range: 0—50μm ( 0 is off )

5-10-15—50 (optional)

§ Minimum Setting of Sectioning Thickness: 0.25μm

§ Horizontal Feed: 28mm

§ Vertical Specimen Stroke: 70mm

§ Specimen Holder Rotation: at any angle within 360 degrees

§ Movement Range of the Base of Blade Holder Base: 0-60mm (front to back)

§ Movement Range of the Blade Press plate: 0-23mm

§ Specimen Clamp Rotation: at any angle within 360 degrees

§ Specimen Orientation: XY – 8°

§ Maximum Specimen Size:70×70mm (optional clamp)

§ Feed speed adjust: 1500μm/s ~ 3500μm/s

§ Precision Error: ±1%

§ Working Voltage: AC 220V±10% 50Hz (standard model); AC110V±10% 60Hz

§ Power: 150W

§ Dimensions: 580× 475× 340mm(W×D×H)

§ Net Weight: 41kg

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG