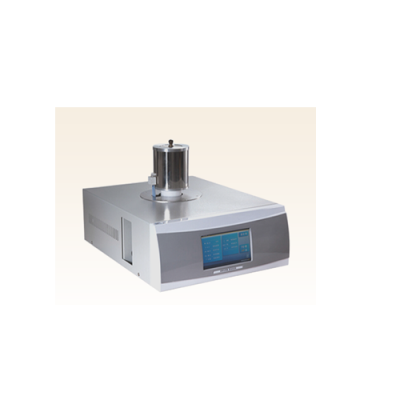

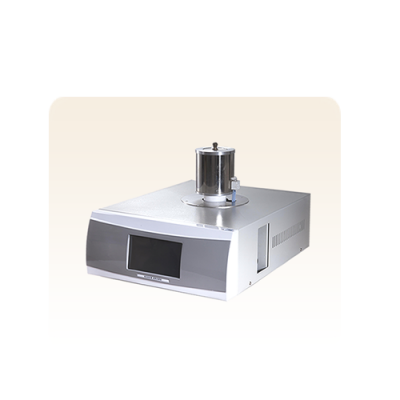

Thermal Conductivity Tester

Thermal Conductivity Tester (New Type)

Model ID: HCDR-S

Product introduction

HCDR-S is a thermal conductivity tester developed by TPS, which can be used to test the thermal conductivity of different types of materials. The transient plane heat source method is the latest method to study the heat conduction performance, which makes the measurement technology reach a new level. It can measure thermal conductivity quickly and accurately when researching materials, which provides great convenience for quality control, material production and laboratory research. The instrument is easy to operate, the method is simple and easy to understand, and will not damage the tested sample.

Working principle

Transient plane heat source (TPS) is a new method for measuring thermal conductivity. It was developed by Professor Silas Gustafsson of Chalmer University of technology in Sweden on the basis of hot wire method. The principle of measuring the thermophysical properties of materials is based on the transient temperature response produced by the step heating disk-shaped heat source in infinite medium. A plane probe is made of thermal resistance material, which is used as heat source and temperature sensor at the same time. The relationship between thermal resistance coefficient temperature and resistance is linear, that is to say, the loss of heat can be known by understanding the change of resistance, which reflects the thermal conductivity of the sample. The probe of this method is a continuous double helix structure sheet formed by etching the conductive alloy. The outer layer is a double-layer insulating protective layer with very thin thickness. It makes the probe have a certain mechanical strength and maintain the electrical insulation between the probe and the sample. During the test, the probe is placed in the middle of the sample for testing. When the current passes through the probe, it will generate a certain temperature rise, and the heat generated will spread to the samples on both sides of the probe at the same time. The speed of heat diffusion depends on the heat conduction characteristics of the material. By recording the temperature and the response time of the probe, the thermal conductivity can be obtained directly from the mathematical model.

Test object

Metals, ceramics, alloys, ores, polymers, composite materials, paper, fabrics, foamed plastics (surface insulation materials, sheets), mineral wool, cement wall, glass reinforced composite board CRC, cement polystyrene board, sandwich concrete, FRP panel composite sheet, paper honeycomb panel, colloid, liquid, powder, granular and paste solid, etc., are widely tested.

Instrument features

1. Instrument reference standard: ISO 22007-2 2008

2. With a wide range of tests and stable test performance, it is at the leading level among similar instruments in China;

3. Direct measurement, the test time can be set around 5-160s, which can quickly and accurately measure the thermal conductivity, saving a lot of time;

4. It will not be affected by contact thermal resistance as static method;

5. No special sample preparation is required, and there is no special requirement for sample shape. For a solid block, only a relatively smooth sample surface and a length width of at least twice the probe diameter are required;

6. Nondestructive testing of samples means that they can be reused;

7. The probe is designed with the structure of double helix. Combined with the exclusive mathematical model, the core algorithm is used to analyze and calculate the data collected on the probe;

8. The structure design of the sample table is ingenious, easy to operate, suitable for placing samples of different thickness, and simple and beautiful at the same time;

9. The imported data acquisition chip is used for data acquisition on the probe. The high resolution of the chip can make the test results more accurate and reliable;

10. The control system of the host uses ARM microprocessor, which is faster than the traditional microprocessor, improves the analysis and processing ability of the system, and the calculation result is more accurate;

11. The instrument can be used to measure the thermophysical parameters of massive solid, paste solid, granular solid, colloid, liquid, powder, coating, film, thermal insulation material, etc

Technical parameter:

Test scope:0.005—300 W/(m*K)

Temperature range of measurement sample: room temperature—130℃

Probe diameter: probe 1 7.5mm; probe 2 15mm

Accuracy: ±3%

Repeatability error: ≤3%

Measurement time: 5~160S

Power Supply: AC 220V

Overall power: ﹤500w

Sample temperature rise﹤15℃

Test sample power P: probe 1 power 0 < p < 1W; probe 2 power 0 < p < 14W

Sample specification: single sample measured by probe 1 (15 * 15 * 3.75mm)

Single sample measured by probe 2 (30 * 30 * 7.5mm)

Note: probe 1 measures low conductivity material with thin thickness. If the measured sample surface is smooth and smooth and has viscosity, the sample can be superposed

Compare to other thermal conductivity testing methods:

Transient plane heat source | Laser Method | Thermal Line | Protection Thermal Plate | |

Test Type | Non-steady state method | Non-steady state method | Non-steady state method | Steady state method |

Measure physical properties | Directly obtain thermal conductivity and thermal diffusivity | The thermal diffusivity and specific heat are directly obtained, and the thermal conductivity is calculated by the input sample density value | Get thermal conductivity directly | Get thermal conductivity directly |

Testing Samples | Solid, liquid, powder, paste, colloid, granule | Solid | Solid, Liquid | Solid |

Sample Preparing | No requirement; simple sample making | Sophisticated in sample making | Simple in sample making; but there is requirement on it. | Big sample size |

Testing Precision | Normal ±3%, best precision ±0.5% | Best reaches ±10% | Best reaches ±5% | Best reaches ±3% |

Physical model | Plane heat source contact measurement, as long as the limited surface contact is good | Non-contact heat source | Line heat source, the line model must be in good touch | Heat source contact type, good surface touch is required |

Thermal Conductivity Range [w/(m*k)] | 0.005-300 | 10-500 | 0.005-10 | 0.005-5 |

Testing Time | 5-160S | Several Minutes | About 30 minutes | About several hours |

Price | Cheap | Quite Expensive | Expensive | Very Cheap |

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG